By Charles T. Vono — SAME

How an Oliver Evans’ Mill Produces Flour From Grain

Oliver Evans was an inventor and genius who designed mills and steam engines. The first Evans’ mill was built in the late 1700s and is often used as a convenient starting point for the First Industrial Revolution. In his mill designs, his big idea was setting up innovative machines as a continuous collection of processes to create improvements in the final product and economies of scale — producing better flour at a lower cost. An essential characteristic of his mills is also seen in modern factories:

- Machines are arranged to systematically support

a process. - There is easy access to a central power source.

- The factories accomplish specific missions.

- Economies of scale create better products and reduce costs.

- Easy transportation is needed because efficient output forces the mill owner beyond local markets.

- Division of labor in the factory and among factories creates specialized tasks, such as mills making flour bags for flour mills.

The section provides detailed descriptions of the product flow from grain to flour in an Evans’ mill and, using that description, summarizes the key characteristics of a modern factory.

- A farmer or miller places grain in the mill. The farmer might add the grain to be held in the hopper below until the miller releases the grain down to the bucket elevator. Grain was then carried upward for processing. Sometimes iron combined with grain during harvest or transportation, so magnets were used to separate iron from grain.

- The miller uses machines, hoppers, gates, and gravity to move grain to the appropriate machines.

- At the top of the bucket elevator, the grain drops and is then cleaned by screens, tumblers, agitators and blowers.

- The cleaned grain can be shuttled to one of three millstones, each one tuned to a specific type of grain or grinding.

- Once the product is ground into flour, it takes a ride on another bucket elevator. A machine rakes the flour in a spiral specially sized and timed so that it is cool and dry by the time the flour tumbles through the hole in the middle.

- As the flour falls, it runs through a sifter for more cleaning before being packaged and shipped.

The Essence of a Modern Factory

Many characteristics of Evans’ mills are the same as modern factories. Machines are arranged to create an efficient and effective system that no longer requires employing many workers with specialized skills. Instead, a single power source, the water wheel, runs the entire enterprise. The whole factory has one purpose; for mills, the purpose is creating a final product like flour from an initial harvest like grain. The efficiencies of the machines, speed, and cleanliness lead to large quantities of a superior product and must be transported to ensure that the product can reach its market. The mill also opens up space in the market for factories that supply items used in the mill.

Commercial Space

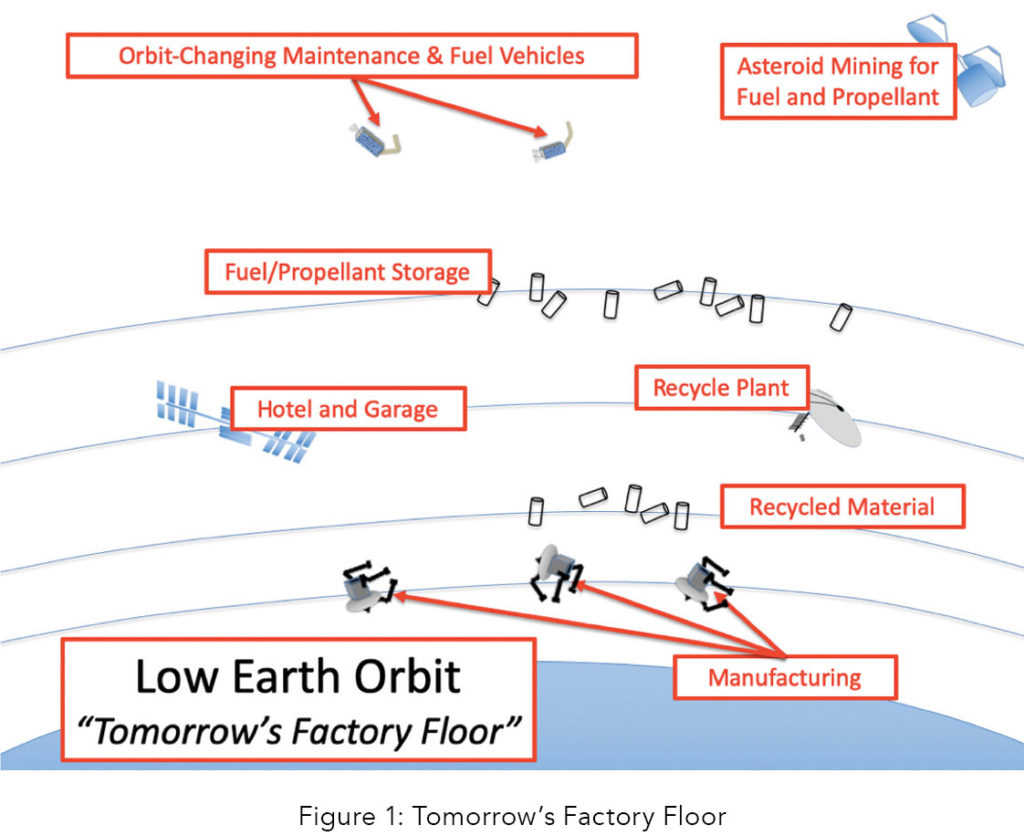

So how does all the above affect 21st century factory floors, some of which will be in Earth orbit? (See figure 1)

Many characteristics of commercial factory space will be the same as Evans’ mill:

- Machines will be arranged systematically to support a process:

They will be arranged in orbit according to the need.

Orbital trajectories will be set up to intercept promising asteroids.

There will be terrestrial support systems.

Some materials will be parked in space for future reuse.

- There will be easy access to a central power source. These could include solar power, onboard nuclear decay, or volatile material from asteroids.

- The space factories will accomplish a mission. For example, the mission might be tourism, satellite maintenance, or unique microgravity manufacturing.

- Economies of scale will be used to produce better products at less cost. Once proven, use of commercial space will grow exponentially.

- Easy transportation will be required since efficient output forces owners to go beyond local markets:

Delivery to Earth is easy because of Earth’s gravity well.

Some products will be created inexpensively and sent to interplanetary space. - Division of labor:

Government agencies such as NASA will perform FAA-type functions.

Orbital debris will be swept off the “factory floor.”

Organizations to recycle material, maintain factories, provide fuel, or take care of other needs will operate as separate enterprises.

The U.S. Air Force and the U.S. Space Forces

It is an old joke that mechanical engineers create weapons, and civil engineers create targets. During the first Industrial War, the U.S. Civil War, both sides targeted mills whether they were highly automated or not. Even when they were not formal targets, they were buildings of great interest. Almost every community had a mill, and Confederate military leaders often used mills as meeting places.

Many battles are named after the mills nearby, which were important community landmarks. General Sherman’s March to the Sea destroyed mills in support of his strategy of leaving behind no resources that could be used by the South. There is a famous story of Roswell, Georgia, where many mills were destroyed. Hundreds of suffering workers had to move north.

In the 1930s, the U.S. Army Aviation Signal Corps created a new military air doctrine based on the experiences of the Civil War, the Great War and the Spanish Civil War.4 Military forces attacked another nation’s industrial strength by flying over entrenched front lines and dropping bombs. General Curtis LeMay played a crucial role in realizing this doctrine in Europe and Japan during World War II and as commander of the Strategic Air Command after the war.

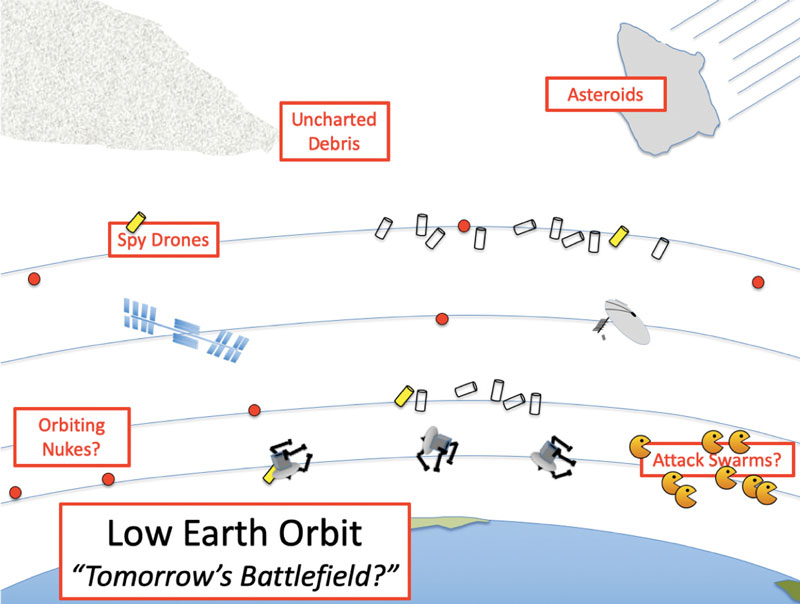

Will commercial space enterprises be like a nation’s industrial strength after the Industrial Revolution? Will it help form the basis for a new Space Military Doctrine that will be the focus for a new U.S. Space Force? (See figure 2)

We don’t know, but here are a few points to consider.

- Maneuvering in space is not the same as the aeronautical flight of a strategic bomber. Orbital dynamics will undoubtedly play as key a role as aerodynamics.

- We do not yet have effective and affordable methods to clear orbital debris. As a result, nations with the ability to wage war in space or near space will have a massive stake in not destroying the industry of their adversaries if that means destroying the use of space for themselves as well.

- Robots are well-suited to working in space: they don’t die. However, the fear of space debris and costs associated with life support will force a more subtle approach of spying and pilfering robots. More aggressive robots might take the form of destructive swarms that clean up after themselves.

- Will some nations choose to hide nuclear bombs among the teeming streets of tomorrow’s orbital commerce? Previous national security calculations made by governments suggest not.

- Natural dangers such as incoming asteroids will spark a large buildup of orbital and terrestrial defenses that will look a lot like today’s global ground-based missile defense system, GMD. Some of these, based on the potential asteroid target, must carry nuclear weapons. But it is most likely these would be launched from the ground using sensors in space to aid targeting.

This article offers no real answers about the future, but I hope it inspires the reader to think about commercial space as the U.S. Space Forces become real.

Charles T. Vono

Charles is an engineer and a pilot who was also a USAF colonel and defense contractor senior manager for several decades. Charles has presented and written extensively on SR-71 inflight refueling, the USAF Space Program, ICBMs, and sustaining complex systems. If you would like more information about Charles or the information in this article, or if you would like him to speak at your event, refer to charlesvono.com.

References

- Oliver Evans and Cadwallader Evans, The Young Mill Wright and Millers Guide (Classic Reprint Series, Andesite Press 2015). The easiest way to find this book is on Amazon.com.

- For instance, fiber optic cables with vastly improved range.

- See the following link: arkansascivilwar150.com/historical-markers/wartime-gristmill-destruction.

- U.S. Government, The Development of Air Doctrine in the Army Air Arm 1917-1941 — Hap Arnold, Chennault, Douhet, Mitchell, Foulois, Drum Board, Alexander de Seversky, General Eaker, World War I and II (USA, independently published in 2017 and sold on Amazon.com).